multistage centrifugal pump|multi stage centrifugal pump diagram : store Learn what multistage centrifugal pumps are, how they work, and what they are used for. . Parker Autoclave Engineers Medium Pressure fittings, nicknamed “Slimline SF”, are designed .

{plog:ftitle_list}

The pressure inside the autoclave will temporarily raise the boiling point of liquids during a cycle. If a proper liquid cycle (which has a slow pressure ramp-down to allow for .

Learn what multistage centrifugal pumps are, how they work, and what they are used for. .Vertical high pressure pumps (Series e-SV) and Horizontal Multi-stage pumps (Series e-HM) .Read More: Different types of Centrifugal Pumps. 2) Vertical Multistage Centrifugal Pump. A vertical multistage pump is a famous centrifugal pump that has more than one impeller. These impellers are mounted on the same shaft if .The range of multistage pumps includes a series of horizontal pumps, MCH, and a range of vertical pumps, MCV. The horizontal types can also be supplied in a self-priming version, MCHZ.

bearing radially split pumps, BB3 multistage axially split pumps, BB5 barrel multistage radially split pumps and overhung OH2/OH3 process pumps. Vertical turbine pumps are available in any configuration including can pumps for low NPSH, fire pumps and submersibles. Design and manufacturing capabilities include standard commercial grades, ASMEAlso known as booster pumps, these have a multistage impeller that propels water about two times higher and farther than standard circulation pumps. Use them in applications such as water delivery, irrigation, and pressure washing. The motor is totally enclosed fan-cooled (TEFC) for use in dusty, dirty, and damp environments. Pumps are gravity fed and require an elevated liquid .

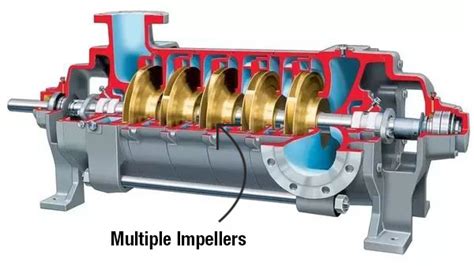

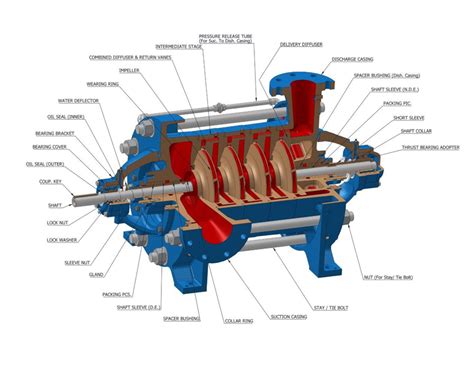

Assume that multiple, two-stage centrifugal pumps in parallel are used. Assume that the first stage performance is shown in Figure 1, and second stage performance is shown in Figure 2. Assume that both stages of each pump are equipped with a 29-inch impeller, corresponding to the top head curve shown in Figures 1 and 2. A centrifugal pump’s impeller is what pressurizes and transfers the liquid. Because multistage pumps have multiple impellers, their pressure ranges and flow rates are far superior.. Within a multistage centrifugal pump, each impeller acts like a single-stage pump within a chain of pumps. The advantages of multistage centrifugal pumps stem from this chain-like design.A multistage centrifugal pump operates on the principle of converting mechanical energy, typically from an electric motor or internal combustion engine, into kinetic energy. This kinetic energy is then used to move fluid through multiple stages, increasing its pressure and enabling it to be transported over long distances or to higher .Multistage pumps are defined as pumps in which the fluid flows through several impellers fitted in series.. The head of a single-stage centrifugal pump is largely governed by the type of impeller and the circumferential speed. If the rotational speed cannot be increased due to other operating conditions and a larger impeller diameter would lead to very low specific speeds resulting in .

Industrial Duty Multistage Centrifugal Pumps Designed for long-life and trouble free service, the 8K series are a superior line of multistage centrifugal pumps. Originally engineered for booster, water purification, and hot water applications, many other industries have adopted this product due to its reliable performance.Rated among the most common pumps, centrifugal pumps are widely used in industrial and water facilities. A centrifugal pump is designed with a rotating impeller that facilitates the circulation of fluid within a casing. It then directs the fluid to a discharge pipe or outlet. Centrifugal pumps are classified as either single or multistage.Goulds Model 3355 is a multistage ring section pump designed for high-pressure services including: boiler feed, reverse osmosis, shower service, pressure boosting, plus much more. Its modular design and multiple configurations make it ideal for your system.The HPS Cobalt Series Pump is a high-quality multistage centrifugal pump that combines the benefits of a positive displacement pump with the reliability and convenience of a centrifugal pump to provide consistent output across low to high application rates. Designed to help optimize performance for small to medium-sized equipment for applications

Centrifugal Pumps can be fitted with different impellers to accommodate solids or large particles, where as multistage pumps are not designed for solids unless pumps are large or oversized. Liquid ring pumps can handle entrained gas, have lower NPSH and can completely empty a container

multistage pump catalogue

multistage centrifugal pump pdf

VERTICAL MULTISTAGE CENTRIFUGAL PUMPS BVM/BVMX 3 HIGH HYDRAULIC EFFICIENCY, MOTOR DESIGNED TO NEMA STANDARDS The BVM and BVMX are vertical multistage pumps with flanged/NPT or grooved connections. Stage construction with stainless steel impellers, chambers and pressure casing. Pump stub shaft and motor shaft of the NEMA .Variants of the Multistage EDUR-Centrifugal Pump. EDUR offers high-quality multistage centrifugal pumps with the LB, VB, NH and Z series.They are available in horizontal and vertical sectional construction as well as in a variety of construction styles and materials, such as grey cast iron, bronze or stainless steel.Moreover, they can be executed with various shaft seal .

A Multistage type of Centrifugal Pump is a sophisticated pump design built to generate high-pressure output by incorporating multiple impeller and diffuser stages along a single shaft. Each stage consists of an impeller and a stationary diffuser, and as the fluid passes through each stage, it undergoes an incremental increase in pressure.

Multistage centrifugal pumps are widely used, and improving their efficiency is an indispensable part of energy conservation. A multi-objective optimization method combining experimental design, surrogate model, and optimization algorithm is proposed to re-design impellers and diffusers for improving pump performance. In the paper, nine .In-line multi-stage pumps are used in installations in which a high head is needed. Several impeller stages are connected in series and the inlet and outlet are on the same level. In-line multi-stage pumps are used for water supply, water treatment and almost any industrial solution including those for aggressive liquids.most modular pump program in the world, including higher pressure, lower NPSH and the use of standard motors. And of course, the new CRs are also available as combined systems with dedicated CUE frequency converter and as boosters systems. Vertical Multistage Centrifugal Pumps GRUNDFOS EXPANDED RANGE OF CRs APPLICATIONS • Pressure boosting

Multistage centrifugal pumps bring along a host of benefits, rendering them a preferred choice across multiple industries. One of the most significant advantages is their high efficiency. This is particularly crucial in instances where large volumes of liquid need to be transported over significant heights or distances. The multistage design .The vertical multi-stage pump is a trusted and proven workhorse pump found in agricultural and industrial environments around the world. They are frequently selected as a strong solution to common challenges where low flow and high head pumps are required.Vertical Multistage Centrifugal Pumps. Vertical multistage centrifugal pumps have a vertical shaft, with each component stacked one on top of the next. Like the horizontal version, the vertical construction has segmented casing with inter-stage components. However, the vertical construction is a smaller footprint, making it ideal for smaller .

Multistage centrifugal pumps are an important piece of equipment for fluid transportation based on the single-stage centrifugal pump, which could provide high-pressure liquid and is widely used in . The geometrical parameters of the diffuser directly affect the hydraulic performance of the multistage centrifugal pump, among which, axial length L 1, the trailing edge position of vane L 2, vane wrap angle φ 2, inlet angle β 3, and the number of vanes Z 2 have a great influence on the performance of the pump. Therefore, these five parameters are selected as . Sedangkan vertical multistage centrifugal pump sering disebut dengan multistage pump penyangga atau cantilever pumps. Pompa jenis ini biasanya memakai sebuah poros yang unik serta bearing yang dapat membantu suatu konfigurasi dengan tujuan melancarkan volute menahan dalam sump. Di sini bearing berada di luar sump.

#2 Multistage Centrifugal Pump. The multistage centrifugal pump consists of more than one impeller connected in series in the pump casing. In this, the fluid enters from the first impeller under the pressure of the suction line and leaves at some high pressure.Kirloskar RKB series is a horizontal multistage centrifugal pump. RKB/RKBF/RKBK horizontal multistage centrifugal pumps are side suction pumps with vertical delivery and diffuser type casing. RKB horizontal multistage centrifugal pump series impellers are of radial flow type provided with balancing holes.

multistage centrifugal pump operation

lab pipette cleaning

Sterilize by autoclaving. Recipe for the preparation of 20X SSC solution.

multistage centrifugal pump|multi stage centrifugal pump diagram